We can produce C-shaped curved glass and J-shaped curved glass, which are mainly used in quadrant shower enclosures and corner shower enclosures. They’ve been recognized by our customers with precise radian and size, every piece of Apis curved shower glass is a qualified product.

| Items | Description | Tolerance |

| Thickness | 3/16” (5mm), 1/4” (6mm), 5/16” (8mm) | ±0.20 mm |

| Size | 450-2000mm | ±1mm |

| Hole Diameter | 5mm-50mm | +0.5mm |

| Corners | R3mm-R50mm | ±1mm |

| Type | Clear, Extra Clear, Tint , Frosted | N/A |

We can process both Flat Edge and Pencil Edge for curved shower glass. All flat edged glass panels we made have 1mm uniform chamfer edge. They have very smooth hand feeling.

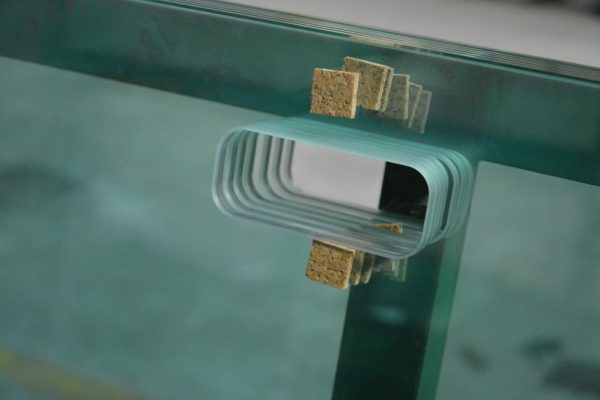

We can manufacture both C bent and J bent curved shower glass. Each piece of our glass panel is with perfect radian, so the two glass panels can joint together perfectly without any gap in between.

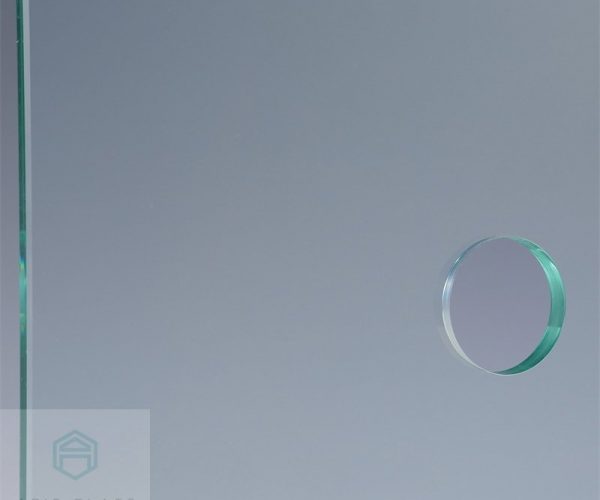

We use automatic punching machine for our curved shower glass drilling, it is featured with precise hole position, and accurate size. As you know it’s very important when you do final installation.

The water-jet cutting edge of our curved glass panels is vertical 90 degrees. The cutouts is of accurate size, and makes it super easy for you to install accessories.

We can print your logo on the curved glass panel for shower enclosures. Three colors optional: white, black, semi-transparent.

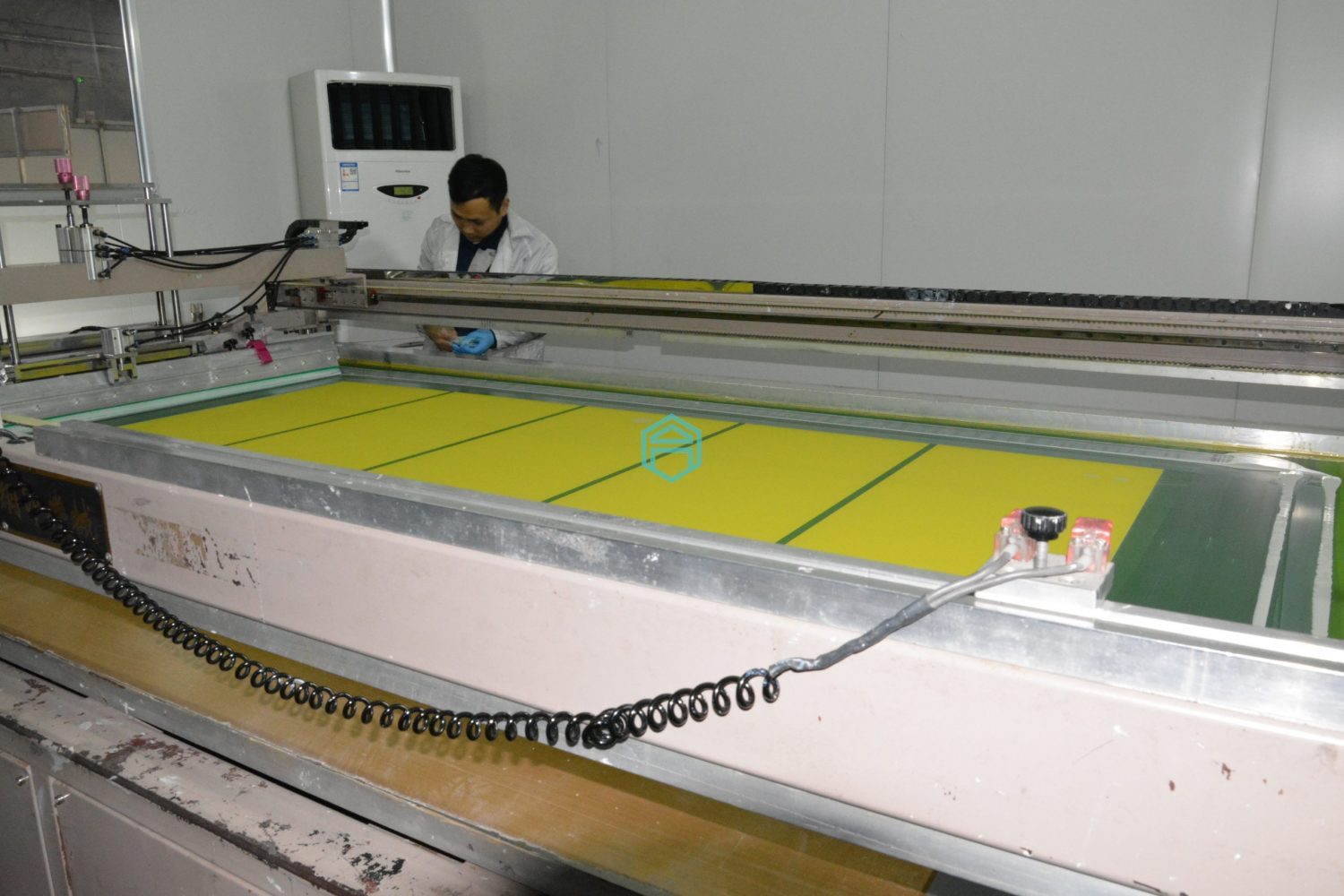

Our frosted glass is produced by silk screen printing, The view effect is very similar to Saint-Gobain’s Santi Glass.

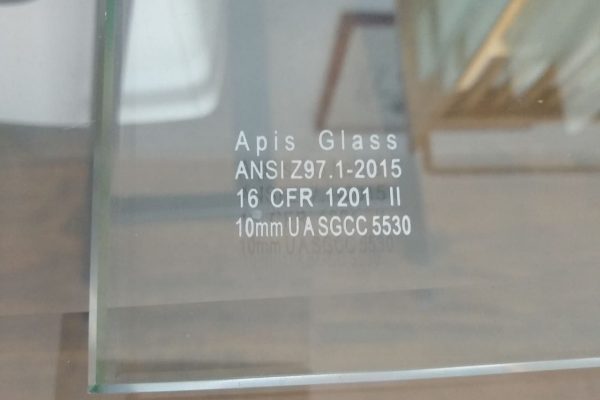

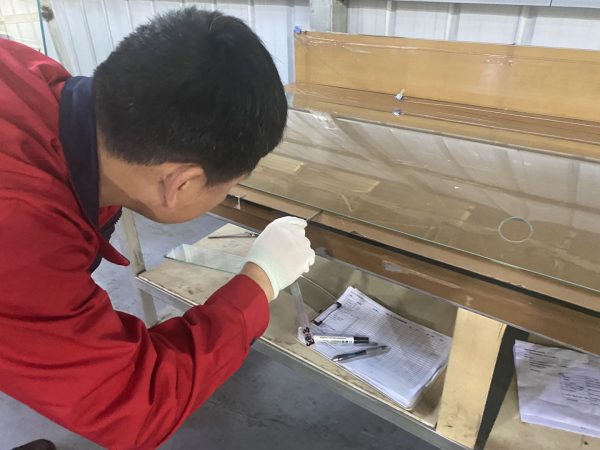

Our company’s internal standards are higher than Standard EN 12150 and ANSI Z97. We inspect the tempered curved glass on each shift: radian, granularity, and record data;

We pursue a range of granularity, which makes the stress of our tempered bended glass uniform and effectively reduces spontaneous explosion.

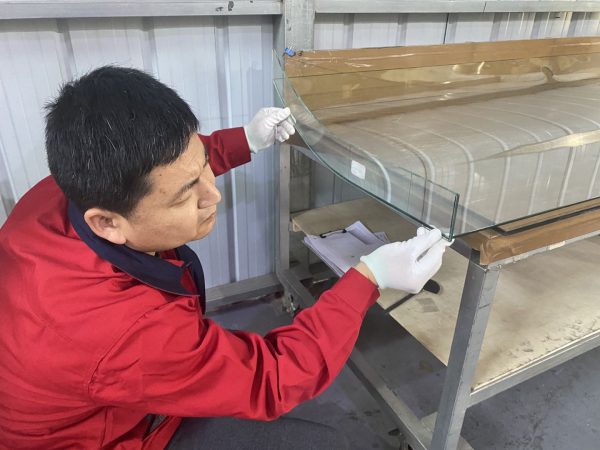

Apis has detailed production standards and strict quality control inspections. We make sure every piece of your curved shower glass panels is a qualified product and can be perfectly assembled.

1. Edge straightness inspection 2. Radian inspection 3. Size and diagonal inspection 4. Assembly test

We use 20mm thick high-strength fumigation-free wooden boxes for curved shower panel package. Each wooden box has a sufficient amount of desiccant, and sealed package. It has 100mm height forklift hole, and use screw fixation.So when you received the package, you can easily transport and disassembly quickly.

We have developed a frosted technology by silk screen printing. Using water-based environmentally friendly ink from American Ferro and Italian Fenzi. The visual effect of our curved frosted glass is very similar with Saint-Gobain’s SATINOVO MATE.

Our painted frosted glass is semi-transparent. It not only allow lights in, but also provide just right privacy. We can also customize a variety of pattern designs like satin glass to fullfill your unique design.

We use liquid of Enduroshield from Australia. Easy clean coating is invisible, non-stick coating on curved glass shower panels that can help reduce the cleaning time up to 90%. It is with 5 or 10 years warranty.

n order to prevent accidental damage to people caused by tempered glass during use, we provide safety film services which you can apply on your shower door glass. It has been proven for 3 years by the market.

It will provide your customers with more safety, especially for elder, children, and pregnant women.

We have an experienced and professional sales team to serve you and fully understand your needs. With our 16 years of valuable experience in interior tempered glass, we can better help you and your brand.